This year I decided to try something I’d been half-jokingly threatening to do for several years. Namely, tap the two big maple trees in my back yard and gather sap to make maple syrup.

I wasn’t expecting this to work well. They’re not sugar maples, for starters; they’re silver maples. Not even the second or third choice for syrup production. They’re big enough, though, and I finally decided to spend a few bucks on some equipment to give it a try. I figured, best case, maybe it would be a little bit of fun and maybe we’d end up with enough maple syrup for a stack of pancakes.

To do this you need a few items. First, you need spiles. These are the taps that get tapped into shallow holes drilled in the tree trunk. Not wanting to spend a big chunk of money on specialized buckets and other stuff that would be of limited or no use and would need to be stored 11 months of the year, I went with some plastic spiles and a bag collection system. The kit came with the proper size drill bit, three spiles, three PVC bag hangers, and three 4-gallon plastic bags. I thought the bags were pretty ambitious.

You’re supposed to start this as soon as the weather starts getting above freezing during the day, and drops below freezing at night. I didn’t anticipate things getting as warm as soon as they did, so I was a week or two late getting the supplies ordered. I honestly figured I’d probably missed the window to do this, but decided to give it a shot anyway. Once I had everything together I headed out to the back yard with my cordless drill, the spiles, a small mallet, and the collection bags. I picked the larger of the two trees to start with.

I’d already marked the drill bit with some tape at the proper depth, about 2”. I drilled the first hole on the south side of the tree (happily facing the house) and gently tapped the first of the spiles in place. I noticed that it immediately started dripping clear, watery sap. That surprised me. I hung the bag on it, and saw it was dripping regularly – about once per second or so.

Moving to the other tree, I repeated the process there. This time the tap started dripping even faster, nearly twice a second. This was looking much better than I ever thought it would. Since I had a third collection setup and the first tree is actually large enough (according to my online research) to support as many as three taps, I started a second one about a quarter of the way around the trunk from the first one. All three were happily dripping away, much to my surprise.

I went back in, but couldn’t help look out the window often to check on the progress of our little maple syrup production line. I saw the bags show a little collected liquid in the bottom. Then it looked like there was about a cup in each bag, with the tree on the left (west) side outpacing the other one. Then it looked like maybe a pint. I checked often throughout the afternoon, amazed at the rate at which the sap was running out of those trees. By 5 PM, I decided I’d empty the bags. Much to my delight and amazement, I got about three gallons of sap total. Before we went to bed I’d collected another gallon or more.

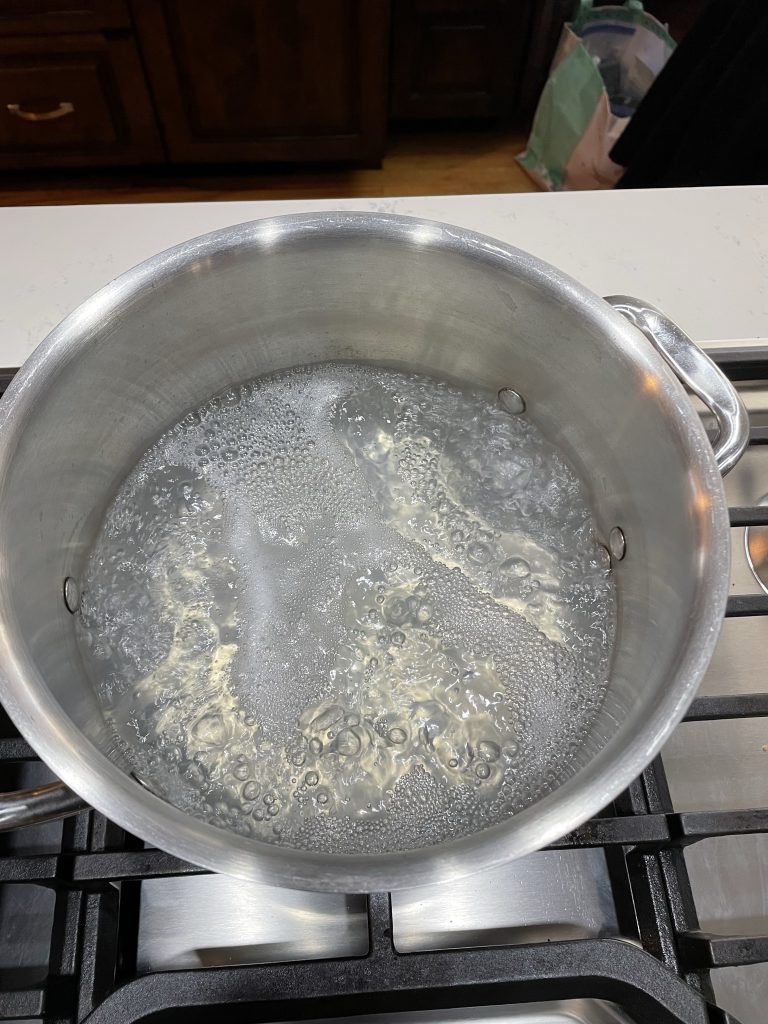

Maple sap is clear and looks like plain water. The sugar concentration, depending on several factors, can range from 1 to 3 percent sugar. I tried a little sip; it’s very, very slightly sweet. Maple syrup is, by definition, 66% sugar. To get from sap to syrup takes a lot of evaporation by boiling. You’ve got to boil 5 gallons of sap down to about a pint of syrup… or even less. Everyone will tell you this needs to be done outside. Needless to say, I tried it in the kitchen. A couple of hours of boiling sap down in a stock pot got me maybe 1/10 of the way there or less, but at least the sap – reduced by about half – actually tasted a little sweet. The humidity, however, was rising in the house to the point that I decided enough was enough and shut off the burner.

That was yesterday. Today was overcast, colder, and raining. We probably got another gallon or so from the collection bags, maybe a bit more. Combined with yesterday’s collection and after the boiling, there was about 4-1/2 gallons or so. Not bad for the first try, started late in a suburban back yard. Being struck with what seemed like a good idea, I brought the 18 quart roaster oven up from the basement and filled it with sap, then turned it on and let it cook for a few hours. Unfortunately it’s just not up to the task of boiling that much liquid with the lid off. I can’t see the point to trying it with the lid on, since the whole point is to reduce the sap by evaporation. On the bright side, I figure half an hour at 180 degrees will kill off any bacteria and hopefully render the sap good for a couple more days until I can set up the propane turkey fryer for some serious boiling. I’m also hopeful tater can get another few gallons of sap before it’s time to call it quits until next February.

More to come…