When I bought the Heathkit SB-101, the dial drive was a mess. The dial itself, of course, was old and severely cracked. Much worse, though, was that FedEx had dropped the rig on its face – and even though it was bubble wrapped, whoever packed it didn’t bother to put Styrofoam blocks between the knobs. That would have protected the face and knobs, but as it was the main tuning dial was damaged. The aluminum skirt was bent, and the drive pulley was damaged.

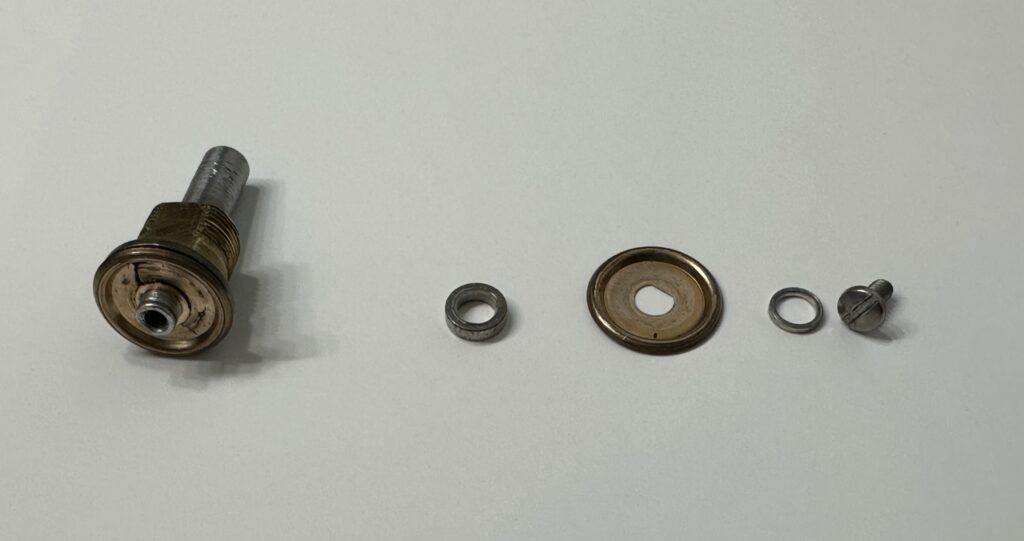

The drive pulley consists of a pair of bronze washers, each with a rolled bead near the outer perimeter, which are spaced slightly apart using a tiny aluminum spacer. That assembly grips an aluminum drive ring that’s attached to the plastic dial. The raised beads put pressure on the drive ring to turn the main dial. Well, on mine, one of those bronze washers is cracked and bent. I was unable to get it sufficiently straightened out to give a solid grip on the tuning drive ring all the way around, so the knob would slip on the dial. Of course no replacement parts are available anywhere, other than from a parts rig – which I don’t have.

With nothing to lose, I decided to try something new. I got the damaged washer as straight as I could, then grabbed a 2 x 5 mm silicone O-ring left over from a coffee machine repair. I put that around the spacer in between the bronze washers and reassembled the mechanism. Success! The operation was now smooth, positive, and free of the slippage I’d experienced before.

After a few days of use, however, I noticed some slipping again. I suspected there was a little oil or grease that had migrated to the O-ring, and I was right. I pulled the assembly apart and thoroughly cleaned everything with some 91% isopropyl alcohol and paper towel. When I re-assembled it, I used a #009 neoprene O-ring. It’s very close to the 5 x 2 mm O-ring I had in there before, but I was hoping that the very slightly smaller cross section and the neoprene material might give a little more traction. I also used a Q-tip with a little alcohol to clean off the dial drive ring, in case there was oil or aluminum oxide on that.

With everything back together, I once again had smooth, positive drive with no slipping. Time will tell how well this fix holds up, but it’s definitely better than the nearly unusable state in which I received the rig.

So far the tuning dial has worked out OK. If it fails, I have a vague plan for a 3D printed center hub for the dial with a ring gear, and a pinion gear for the dial shaft. I understand why this might be one reason the HW-100 is more popular than the SB-100/101/102, but this may also help some owners of other SB-line gear like the SB-300/302 and 400/401.