I’ve moved the blog to a new web service… one of the AWS virtual server offerings. So far, so good… and dirt cheap.

A couple months of Mercedes ownership

I’ve been adjusting to “semi sort of exotic” V12 ownership. Early May I bought a Mercedes S600 with under 48K miles on the odometer. If you’re unfamiliar, it’s an exceptionally opulent luxury sedan with a 510 HP, twin-turbocharged 5.5 liter V12 and an active hydraulic suspension system, among other things. It hasn’t been trouble-free, but I don’t think anything new has broken since I bought it — it just had problems that weren’t obvious when I looked at it. If I’d have had a proper dealer PPI done, I would have screwed the price down a few more thousand — but the logistics of doing that in a distant city are difficult to say the least. Next time (and there will be a next time), I’ll do it differently.

The real adjustment is in how these things are serviced. Got a problem? Unless it’s something mechanical that’s obviously broken, you’re going to absolutely need the Mercedes dealer level software (at the very least), on a dedicated laptop, and the hardware to get it to talk to the car. Period. Or, you take it to a dealer that charges a $160 “diagnostic fee” per symptom. Or, you find an independent shop and hope they’re as good as they claim. The mechanical systems are very complex. The electronics are far, far more complex. Just an example: You turn the thumbwheel on the dash air vent to control airflow. It’s not a mechanical control. It’s a potentiometer, which is read by a control unit that sits on the CAN bus, and talks to numerous other control units, and a decision is made how much to move the electrically actuated damper behind that vent. Oh, the potentiometer went bad and can’t be read? No A/C for you, pal.

I’ll be about $3K deep in repairs, parts, and vehicle-specific tools by the time I’m done, maybe a little less. The good news is, half of that is the one thing that the dealer HAS to do — the rest I can do myself with parts sourced from Fleabay or a couple of dealers that sell factory original parts at a deep discount. By the weekend I’ll be equipped to do anything the dealer can do diagnostic-wise, which will pay for itself quickly.

On the plus side… the thing is over-built, and the level of engineering and the build quality is fantastic. Even at 13 years old, this car has features most new cars don’t. You can cruise all day long in ridiculous comfort (the massaging seats help), and if the mood ever strikes you to see, for example, how long it takes to go from 40 to 130 MPH… it will happily and very quickly do it, without drama, and you’re nowhere near the top end. This model is limited to 157 MPH, and it will easily do it. It’s not going to be as cheap to own and operate as my F150, for example, but once it’s fully sorted out I don’t think it will be punitively bad, either. You don’t own a car like this (or a Ferrari, or a McLaren, or a Bentley, or whatever) because it’s cheap.

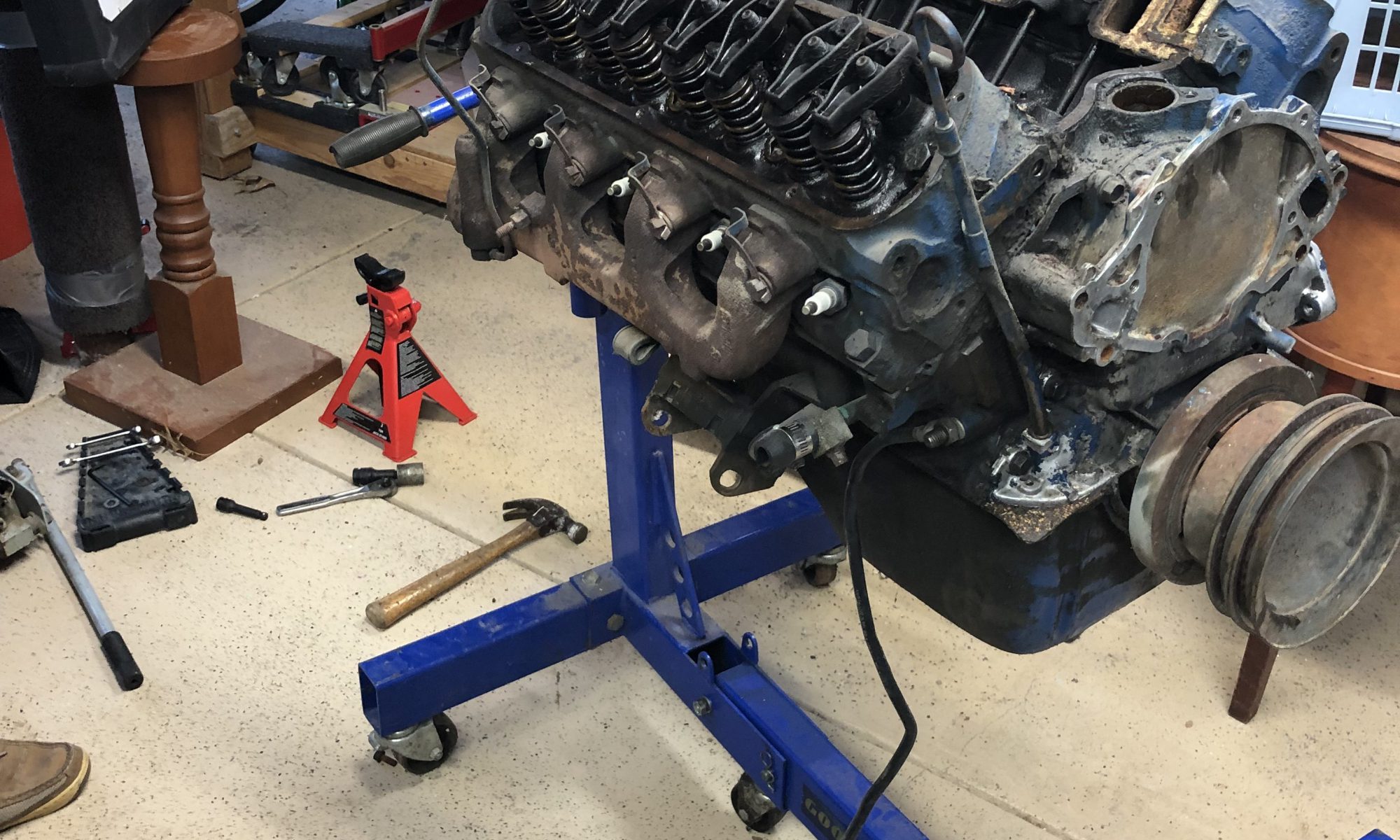

Engine progress

It’s been a while since I posted an update, but it’s not like anyone is following this anyway. 🙂 The engine is out, and on the engine stand. I ended up buying a new hoist from Harbor Freight on sale. Getting the engine pulled was relatively easy, especially once we figured out there are bolts holding the flex plate to the torque converter.

The cam and lifters are junk. Lifters are worn completely flat, so they’ve got to go — this was expected. Plus, a new cam should really wake the engine up anyway. No surprises there. Timing chain isn’t too badly worn from what I can see, but that doesn’t matter either since it’s getting replaced.

The heads are off and look about as you’d expect for a 93K-plus mile engine. In my humble opinion, the valves are probably not worth saving. There are grooves worn in the ends. I’m going to look for some GT40 or GT40P heads locally, since they breathe much better anyway. Slightly larger combustion chambers, but not enough to really hurt performance — especially with a new cam that can more than make up for it.

Pistons and bores look great. Cylinder bore wear is .003 or less, except for #5. That one is more like .006, with about .004 taper. Bore, or hone? I don’t know yet. Honing would save several hundred dollars on the cost of the rebuild. The machine shop wants around $300 for a bore & hone. Add to that a couple hundred for new pistons. If I can just hone, then I can re-ring with new moly rings and save close to $500. I’ll do some more measuring and get some expert advice before making a decision. I’m not building a race engine here, so there’s really no need to sink thousands into it.

All of the main and cam bearings look good, no scoring or signs of uneven (tapered) wear. The crank measures within about .001 of spec, so no work needed there assuming it’s not bent – and no reason to suspect it is.

All in all, it looks to be in better shape than I anticipated. It was definitely time for an overhaul, though. I’m sure the valves weren’t opening fully. Given the wear on the lifters and valve stems, I suspect the cam lobes are worn a bit as well. Cylinder walls had no crosshatch left, and there were signs of a little surface rust from sitting for a few years. I think it will benefit greatly from a slightly hotter street cam, better heads, a 4-barrel, and new rings on freshly honed cylinder walls.

More disassambly

Last night I got a little garage time. I pulled one valve cover, just out of curiosity to see what kind of shape things are in. There were no surprises; the engine seems to be in its original condition with 93K miles. I do see evidence that it’s been worked on over the years, of course — blue Permatex everywhere. No clear sign it’s been overhauled though.

I got the carburetor removed, and pulled the intake manifold (a first ever for me). I’m not going further with disassembly until it’s on the engine stand; in fact, I’ll put the valve cover back on to avoid dripping oil when we pull the engine. But, it’s easier now to get to parts of the engine and the various lines that will be disconnected prior to removing it.

Rearranging…

I took advantage of the good weather this weekend, and my wife’s suggestion, to do some cleanup and rearranging. I got the Mustang down off the jack stands, and we rolled it out into the driveway. I moved the big workbench, the mobile tool bench, and some other stuff to the second garage bay. In between moving stuff around in the garage I got out the power washer and cleaned up the front suspension, engine bay, rear springs, etc. Whatever I could reach without soaking down the interior too much, since there’s still a dash in there. I managed to get a lot of mud, crud, old grease, and some undercoating blasted off.

Once that was done, we got it turned around and into the third bay, nose-in so the front end is near the tool chest. It should be easier to work on now, since I won’t have to walk all the way around the car every time I need a tool. There’s enough room to work – there could always be more space, but it’s an improvement over the way it was before.

A little Mustang update

Last night Lisa and I attended our first MCCO meeting. It seems like a pretty decent crowd. We had a devil of a time finding the place, and didn’t know that all the Mustangs were parked out back. As a result, we didn’t actually see a single Mustang all night! We went ahead and joined. Also got the ENWICC book; I had no idea there were THAT many car club events going on in this area. Or that ENWICC existed, for that matter. Anyway, I think the club will be a very valuable resource for finding places to do media blasting, welding, body work, upholstery, etc.

Now, where was I? I’ve got both fenders off, hood off, etc. I drained and removed the radiator, got the fan and alternator off, and am working toward getting the engine out. There’s almost enough room in the garage for an engine stand. Also got some spring compressors, so I’ll be able to tear out the front suspension for IRAN (Inspect and Replace As Necessary).

The trunk floors… well… not entirely sure what approach I’ll take there. I really would like to avoid pulling and replacing both trunk floors. I may just mark out and cut out square patches on both sides where the rust is, then weld in patch panels. I guess it depends on how far this goes. Given the mount of rust remediation and patching that needs to be done on the rear quarters, I’m thinking I may farm all of it out to a restoration shop — now that I have a couple of them identified.

All of this restoration work has got me thinking about the pickup as well. I think I’ll start getting the underside of that cleaned up, the minor surface rust addressed, paint touched up, and make sure it won’t rust again.

It runs…

I’ve had the battery on a slow charger/maintainer for a couple of weeks. I had assumed the thing was toast, since it was stone dead when I got it… battery voltage was under 0.5 V. I had to use a battery drill pack to throw enough of a charge into it to get the charger to even try to start charging. Every day or two I’d go out, disconnect the charger, run the heater blower for a few minutes, and re-connect the charger. It wasn’t costing my anything, so I figured – why not?

Saturday afternoon, I decided to drop the battery in and give it another try. It cranked over OK, but of course the carb was bone dry. I gave it a shot of ether, and lo and behold — it fired up and ran. I ran it for a total of about 15 minutes or so, until the garage filled with gray smoke and I had to air it out. I’m not quite sure if it was just old-engine exhaust smoke with steam, or if it’s burning oil. Nothing has changed my plan to pull and rebuild the engine, but at least we know it runs.

Pete and I also got the left front fender off. The last idiot welded this one up even worse than the right side. A large patch was actually welded on, not just over rusted metal — but over the top of rusted metal covered with Bondo. Awesome job, dumbass. The fender is scrap, even the front corner is rusted out.

I’m debating what to do with the floor pans. If I can get someone who knows what they’re doing to finish welding them in place, great. I’m afraid I may end up needed to remove all the stuff that’s been done and re-do it. I hope not, but it is one option. The good news (aside from the engine running) is, I got the instrument cluster finished up and put back together, and it looks great. Brakes also seem to be in good shape, so that opens up options for getting it on and off of a trailer and in and out of the driveway when it comes time to use a power washer to clean up the undercarriage, engine bay and fender wells. Just blasting off all the accumulated grime and filth will make it easier to work on.

More body archaeology

The fender shield succumbed to my new Dewalt angle grinder in no more than five minutes. Then I spent some time using a scraper blade on my oscillating saw to scrape undercoat and gunk from the fender apron area. Looking much better now.

I started scraping seam sealer from the trunk to see how much work it would be to replace the trunk floor. What I found was about a pound of Bondo covering up several rusted out places in the trunk, fender well, and probably into the quarter panel as well. Obviously someone went to great lengths to conceal some body rot. I was disappointed but not terribly surprised. I did violate one rule of car inspections… I looked at this thing when it was bitter, bitter cold and I didn’t really feel like crawling around on the floor and stuff for an extended time. But, most of this was pretty well hidden. Obviously there will be more cutting and welding than I planned, but it’s not a show stopper. Maybe it’s just karmic payback for the cowl not being rusted out.

I’ve been recharging the battery to see if it’s going to be junk or not. I may just take it somewhere and get it load tested. I’d love to know if this engine runs or not. There’s gas in the tank, and it doesn’t seem to be ruined, so maybe I can get it started. The tank will get drained, though, and possibly replaced… the jury is out on that. It doesn’t LOOK bad, but then neither did the trunk floor.

2/27 Cowl area and fender shields

Tried to remove the rear fender splash shield — sucker’s welded on. But the mount tab for the front edge of the fender is NOT welded. Go figure. The cowl area looks solid and original, but in need of cleaning up and rust removal.

A few more “Before” pics