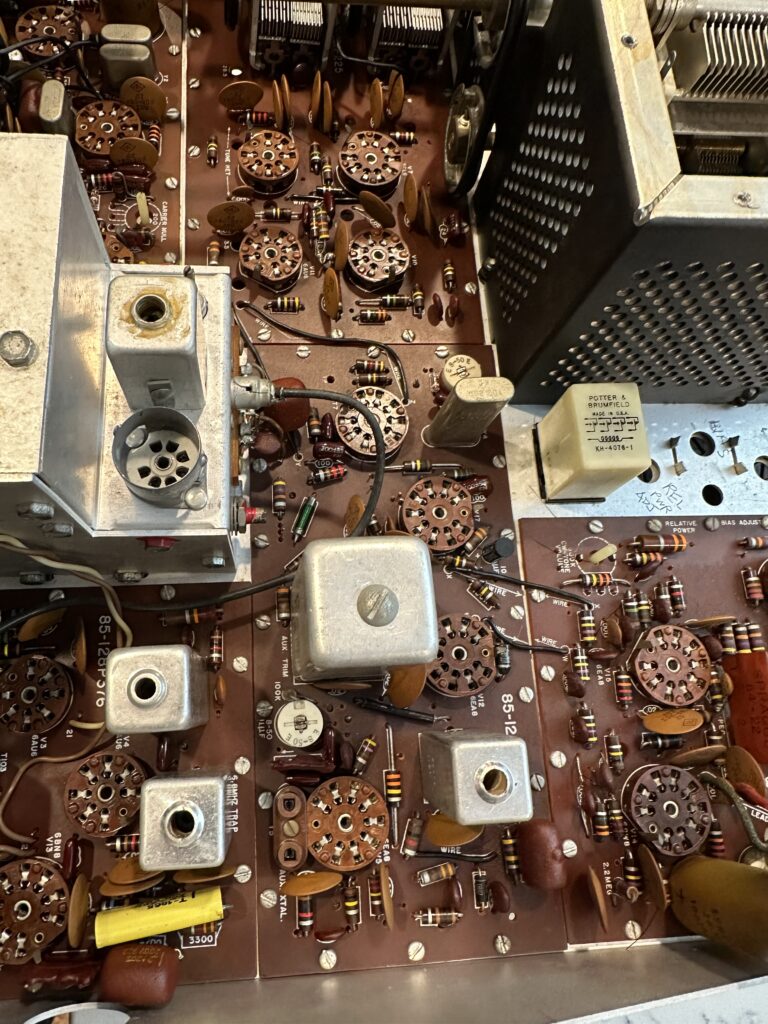

The other day I decided to try setting up the SB-101 and do some testing of the setup with the antenna tuner. As I tuned up with a few watts, things were OK… then I turned up the drive past 50 W, and things got wonky. The monitors on the PC flickered, the PC beeped, it logged me out, the CO monitor in the hallway beeped, and a few minutes later I noticed we’d lost our Internet connection. After a little investigation I found half a dozen GFCI/AFCI breakers in our main panel had tripped and had to be reset. It had dropped power to the entire kitchen, so the router was powered off.

Obviously there’s an RFI problem. I have all of the equipment grounded to a new copper bus bar using 12-18 inch flat copper braid, and the bus bar is grounded to the household AC ground. Ah, there’s the mistake. That puts any stray RFI onto the house electrical ground, which the breakers interpret as a grounding problem.

The shack is on the second floor for the time being, in the “spare” bedroom that has been my office for the past 15 years or so. I’m using a 71′ long end fed wire, with about 18′ or so of counterpoise. I’m feeding it through an MFJ tuner, but that means there’s a good deal of RF on the feedline inside the house before it snakes out through a window.

The eventual solution will be a remote auto tuner at or near the feedpoint of the antenna, outside and well away from the house. The interim solution? Limit my output to QRP levels. I can work some SSB with normal power, but CW or digital modes using much more than that is a recipe for electrical problems. It’s less than ideal, but once our new deck is built I should have a good mounting point for a remote tuner, and a feedpoint from which I can string up a full wave loop for 40 meters that should work pretty well on most other bands too.